兼有高功率和精度

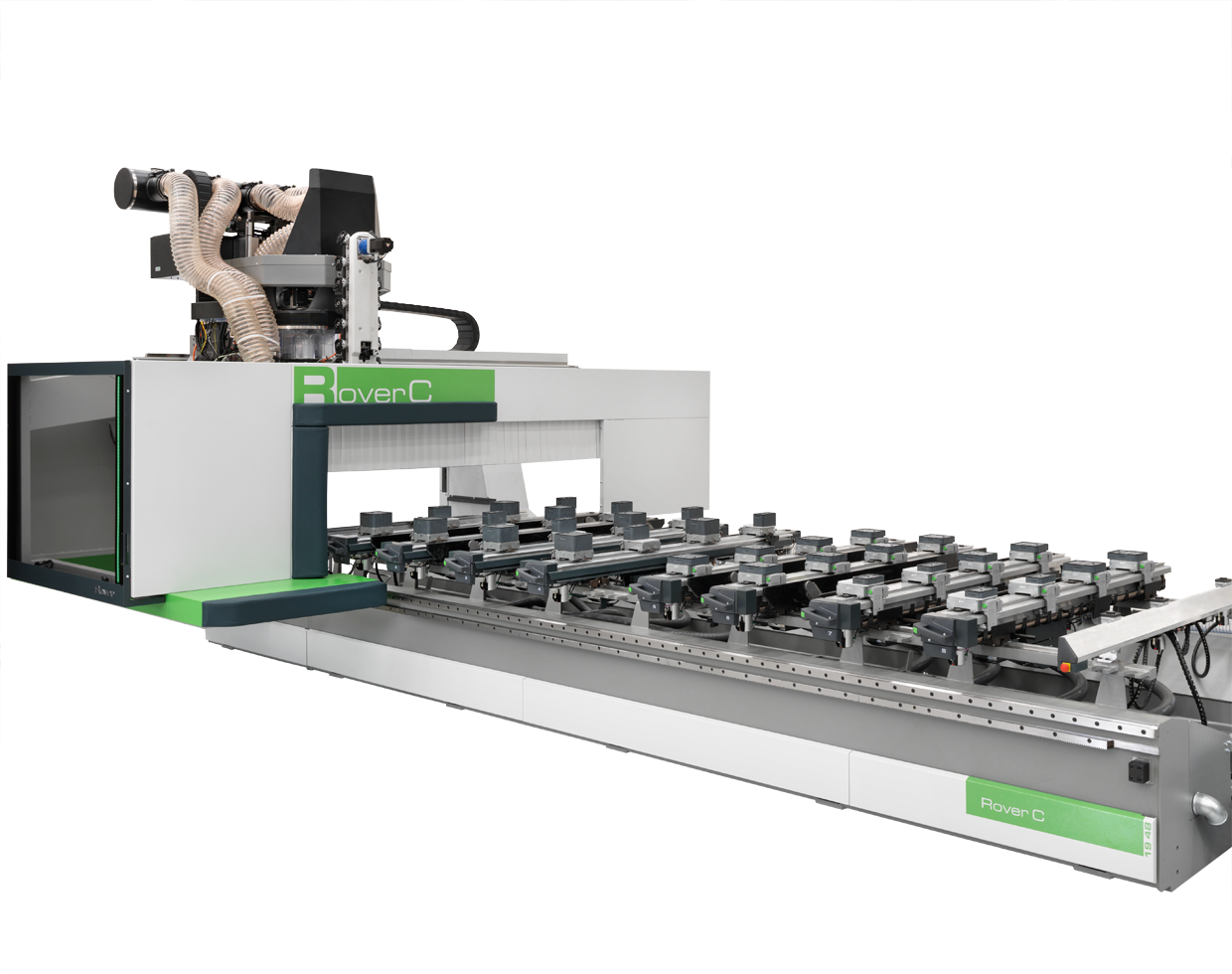

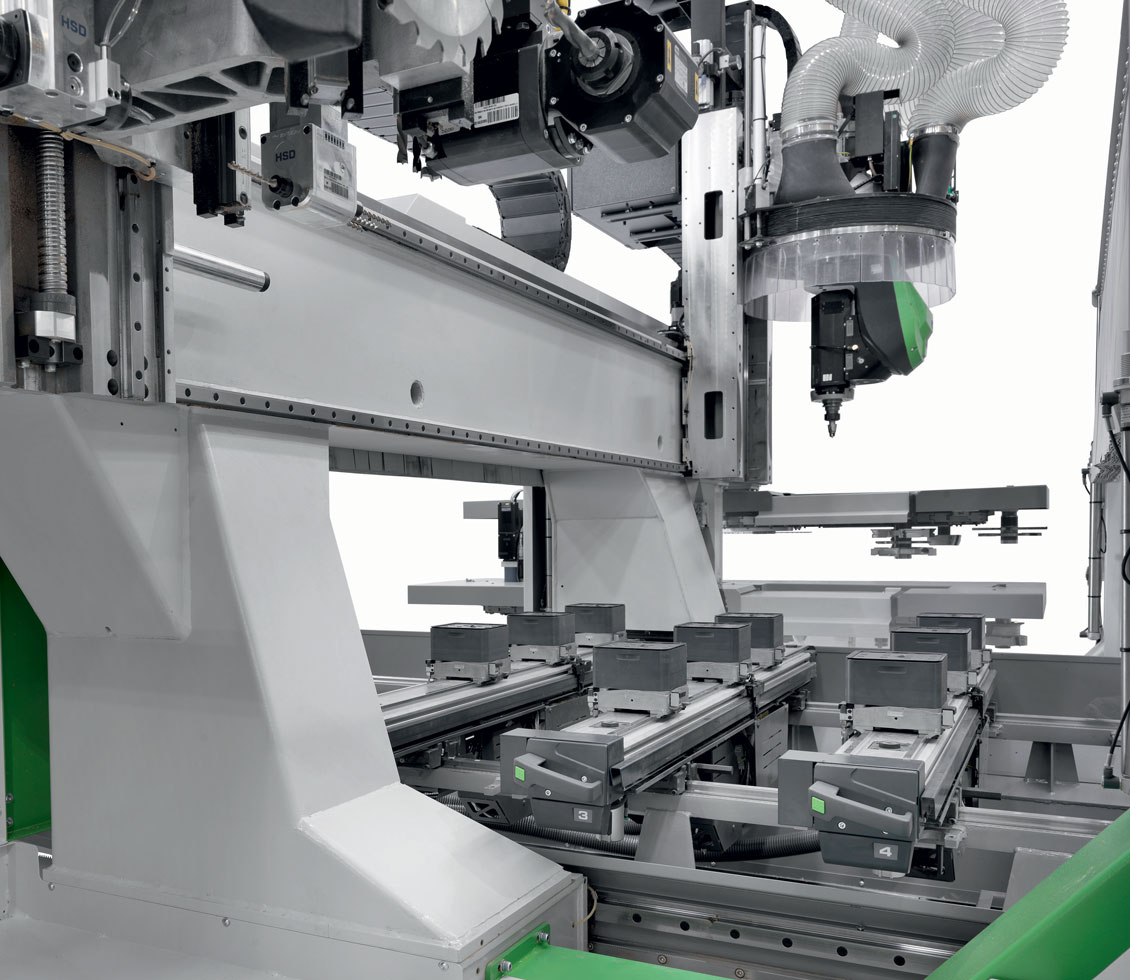

Rover C是一款新型加工中心,可轻松制造任何形状、尺寸和厚度的家具、楼梯和门窗部件,专门用于需要大切削量、大型刀具和组合刀具的重型加工。

我公司可帮助您简化制造过程,充分发挥所有材料的潜力。

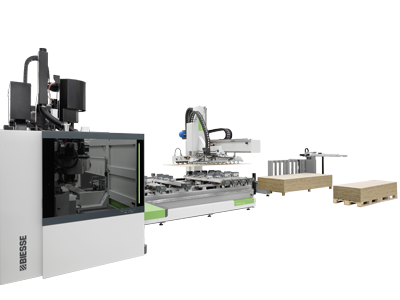

比雅斯为客户提供工厂自动化实用解决方案。

即使在更广泛的工业自动化背景下,ROS 机器人自动化解决方案也能确保生产过程和上、下操作的生产效率和总体可靠性。

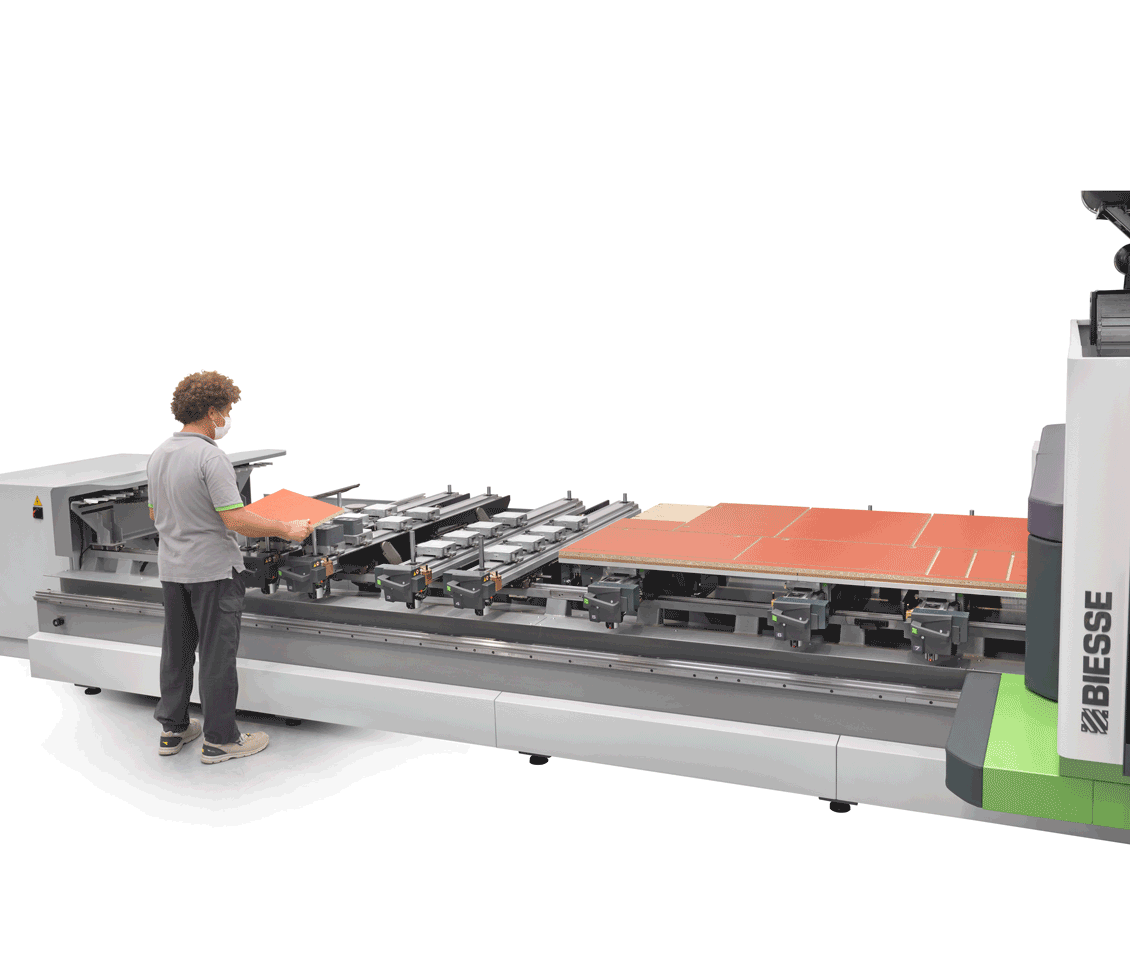

上下料解决方案。用于加工成批板材或门的自动化装置。

Synchro 是一款自动上、下料设备,可将 Rover 加工中心转换为一台自动化设备,无需操作人员即可自动生产成堆板材: