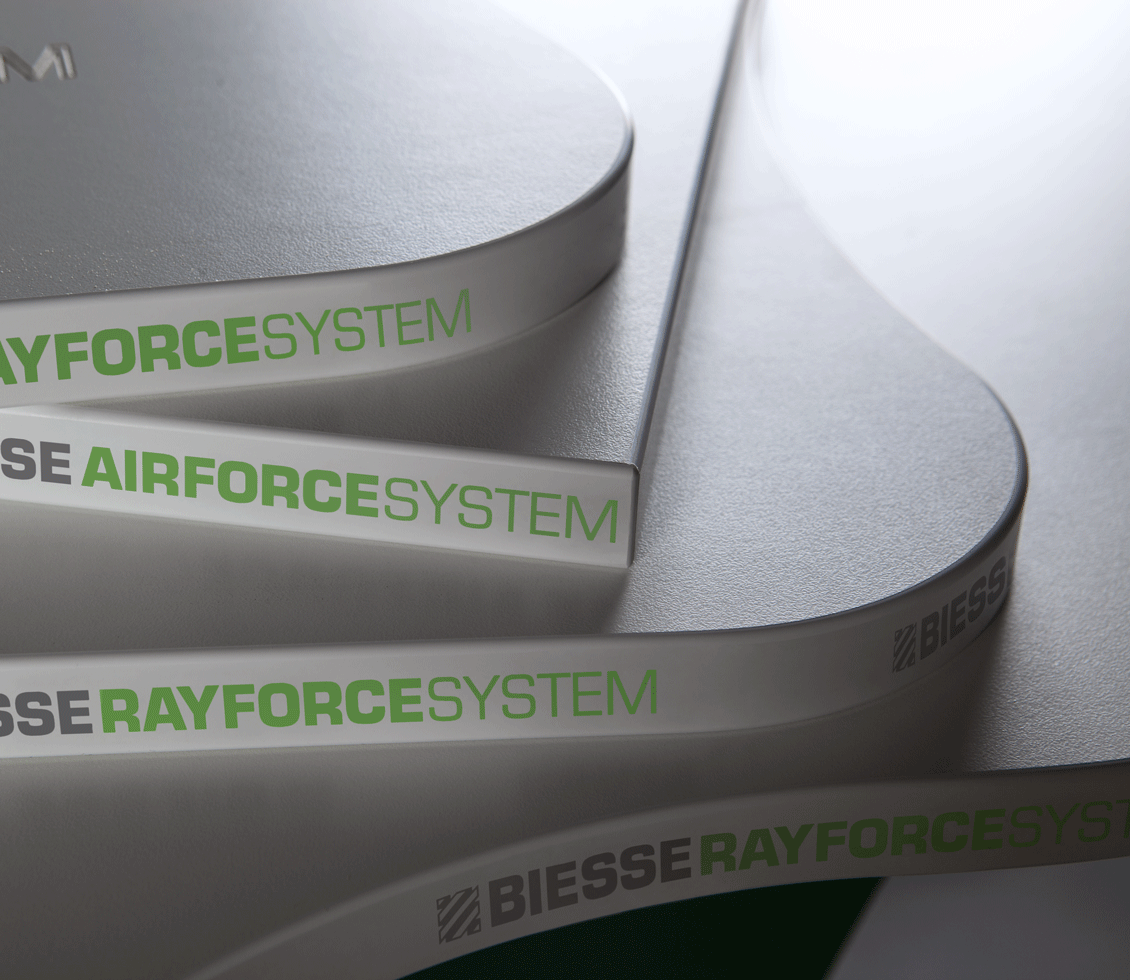

高强度封边

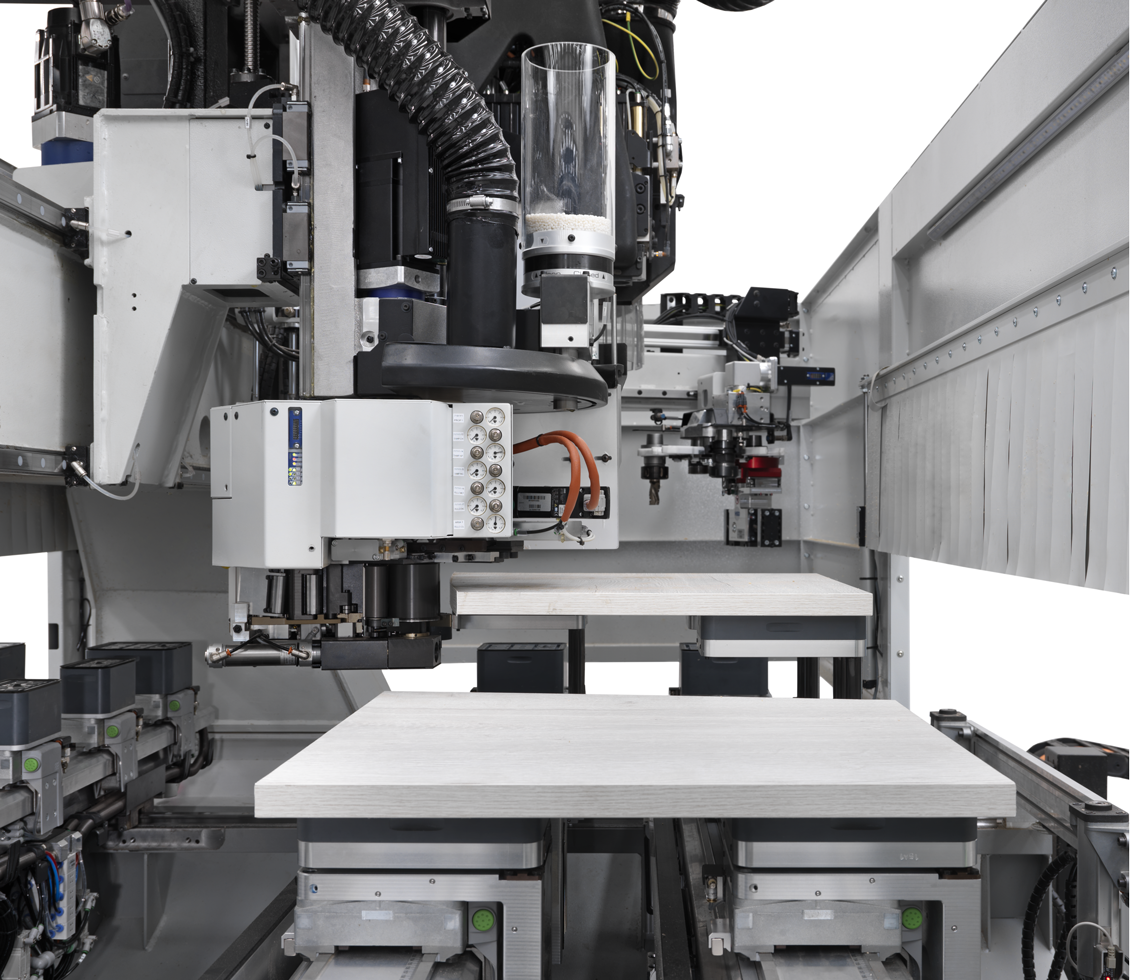

一直以来,封边做法都是将胶水直接涂在板材上;比雅斯遵循这一原则,并将其应用于由加工中心执行的直线封边和异型封边上。最大程度的粘合效果,可以应用薄边和 3D 透明边带,在加工周期内便于进行维护和板材清洁。

我公司可帮助您简化制造过程,充分发挥所有材料的潜力。

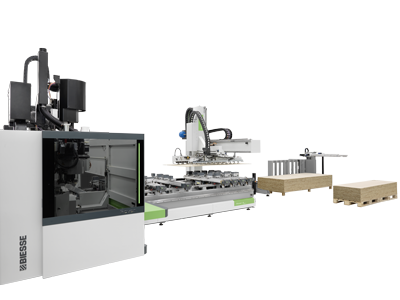

比雅斯为客户提供工厂自动化实用解决方案。

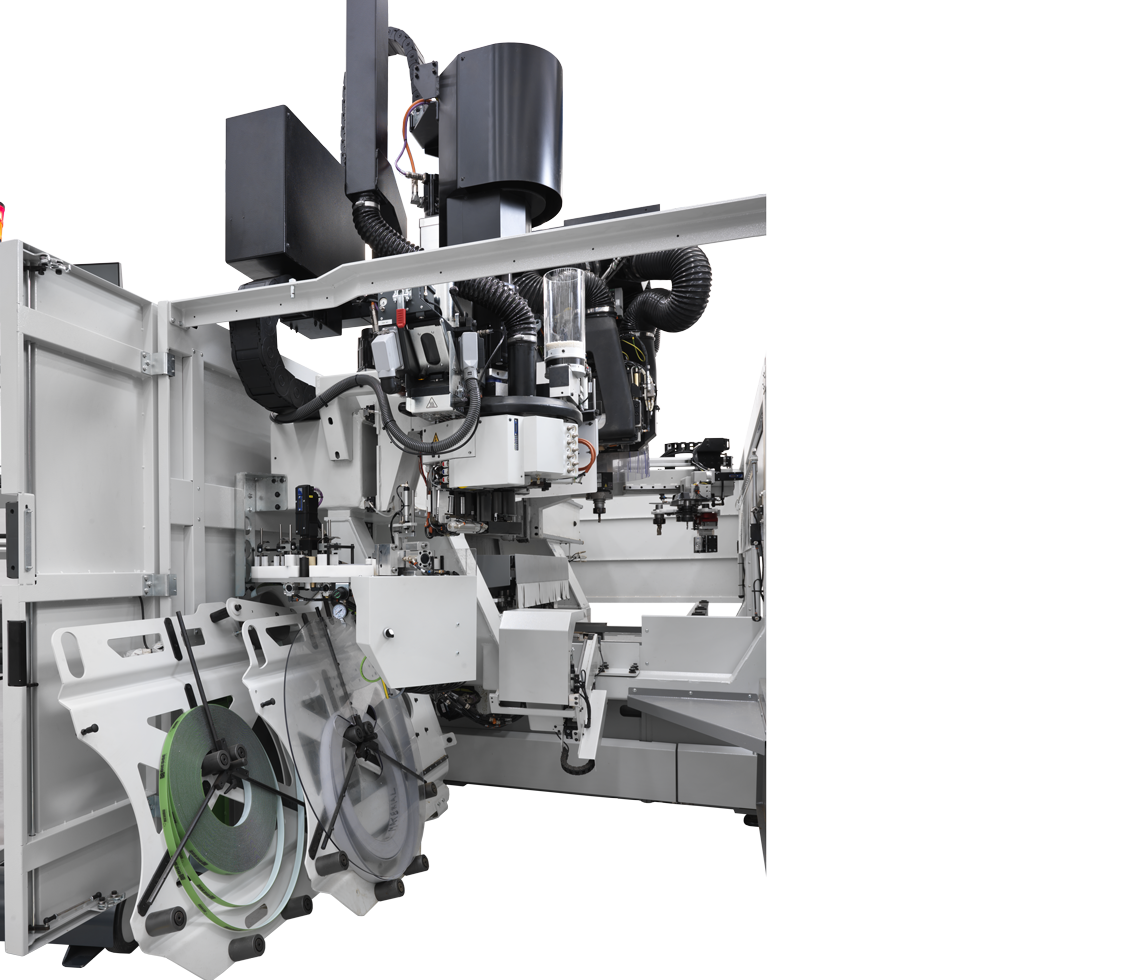

即使在更广泛的工业自动化背景下,ROS 机器人自动化解决方案也能确保生产过程和自动上、下料的生产效率和总体可靠性。

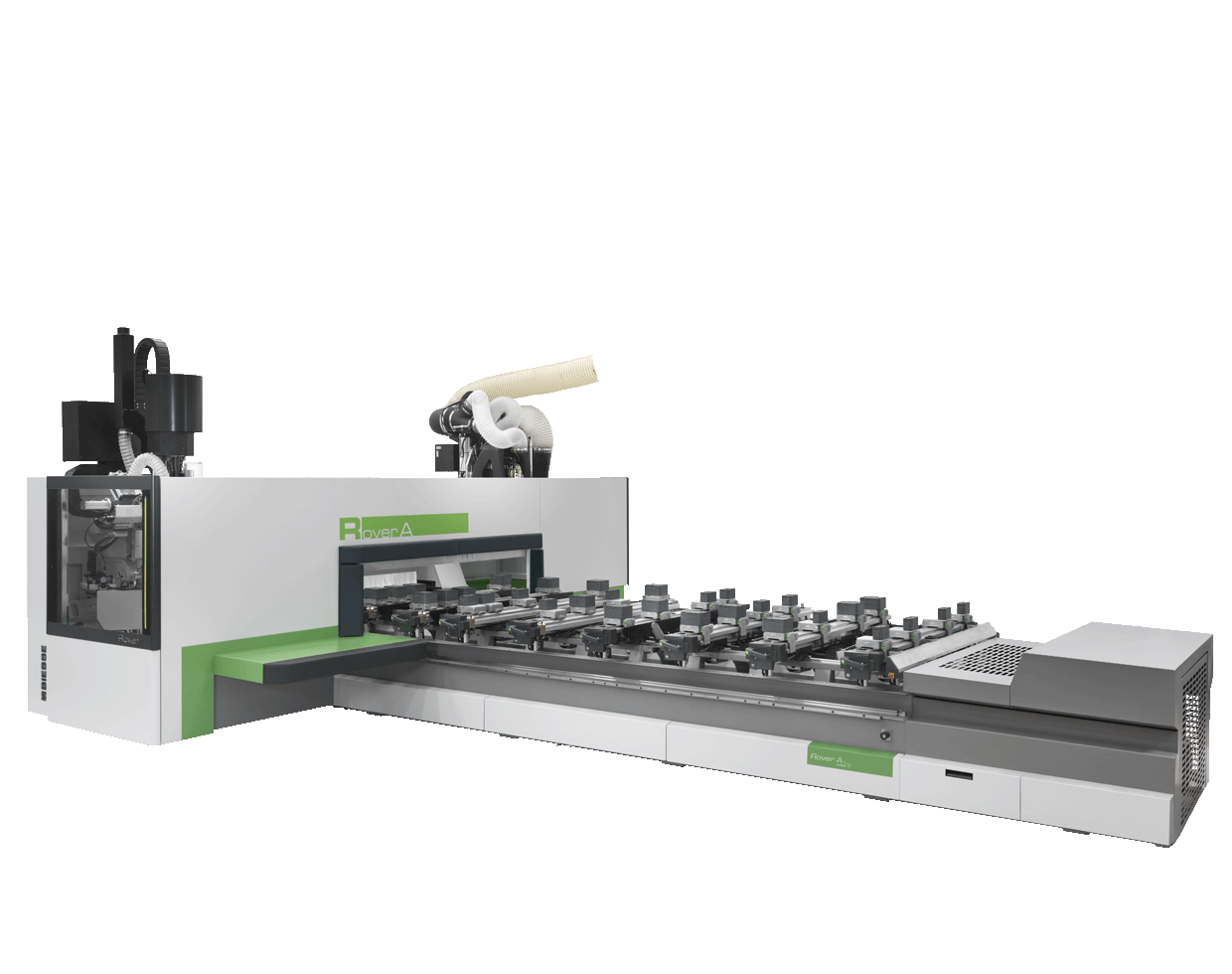

创新型定位系统使您可以充分利用工作台升降优势。

Hyperpod 通过控制工作台升降来执行以前只能在更宽设备上执行的工艺流程。

New hybrid system for melting on-demand glue from above:

- Hybrid pre-melter for working PUR, EVA or APAO glue, to meet every possible need

- High flexibility thanks to the possibility to use glue either in granules or in small cartridges

- Quick and easy maintenance procedures

.png)

上下料解决方案。用于加工成批板材或门的自动化装置。

Synchro 是一款上下料设备,可将 Rover 加工中心转换为一台自动化装置,无需操作人员即可自动生产成堆板材: