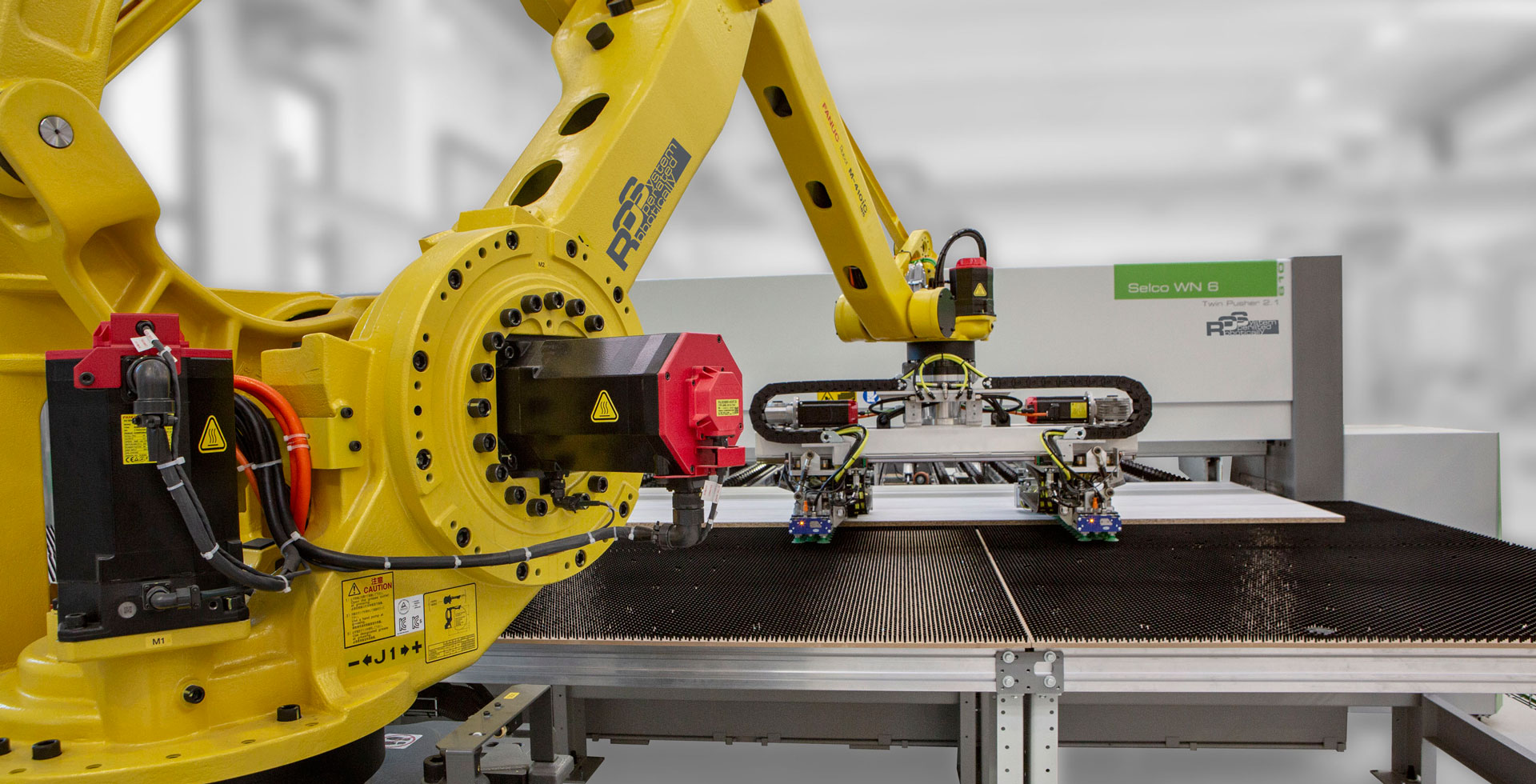

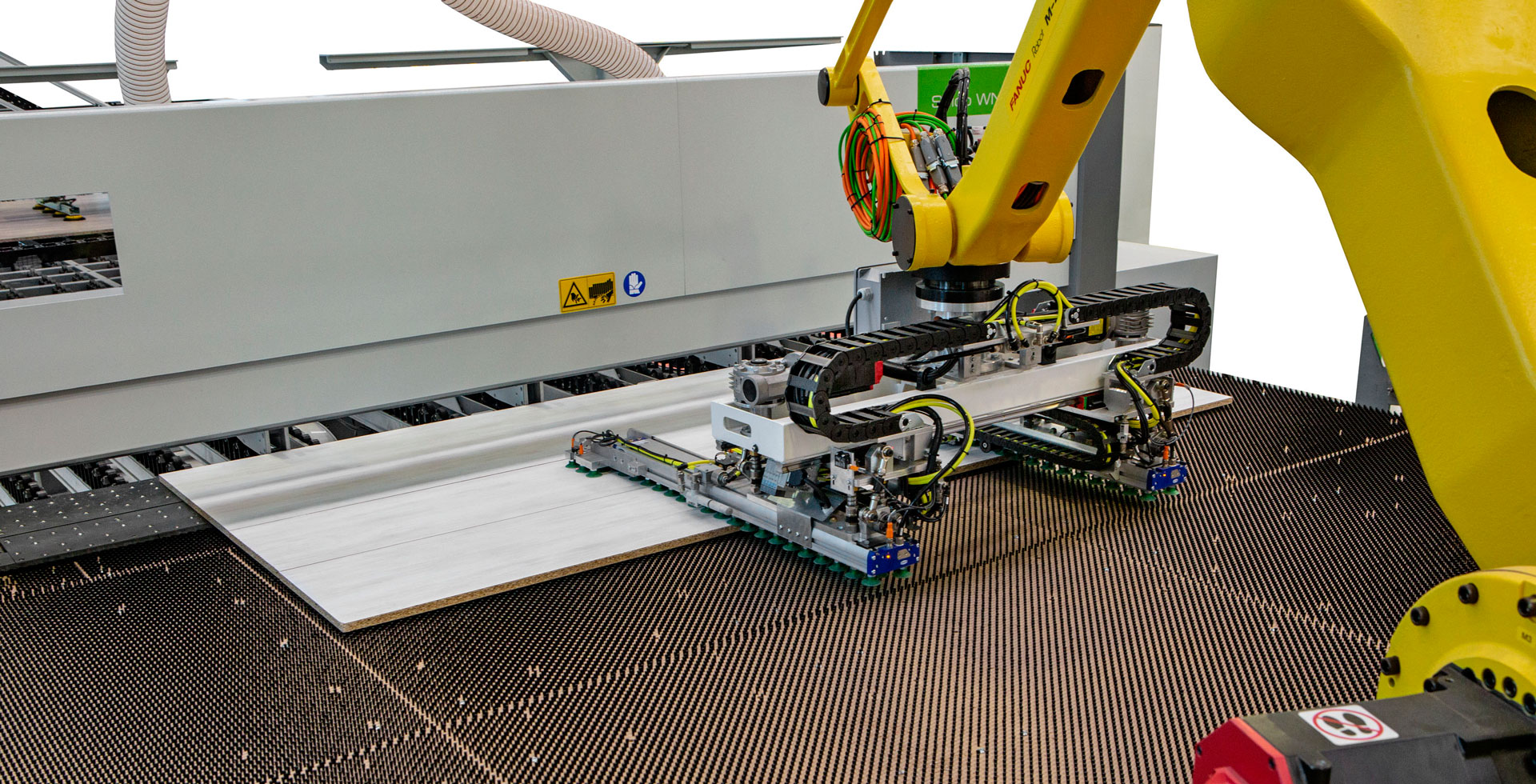

The Factory of the Future: integration, interconnection, automation and digitisation are key to shaping your tomorrow.

Come and redesign your winning production model and enjoy a preview of Biesse’s most innovative technologies, integrated solutions and advanced yet easy-to-use services, along with a host of other new developments ready to shine at Ligna 2019.

Back to Business: Ideas creating a positive change are the heart of innovation.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)